What is Process Cooling?

Unwanted heat in commercial environments is rarely a one-off issue. It builds gradually, through constant equipment use, high-output processes, and enclosed operating environments, until it starts to affect performance. Machines begin running hotter than expected. Product quality becomes harder to control. Energy costs rise without a clear cause.

If you’ve started wondering, ‘What is process cooling, and do we need it?’, it’s a common question in commercial and industrial settings. These systems are designed to remove excess heat generated during operations and keep temperatures consistent where it matters most.

Understanding how process cooling works can help you identify risks early, improve system reliability, and make more informed decisions about your facility’s long-term performance.

Key Takeaways

- Process cooling is designed to remove heat from commercial and industrial operations, not for occupant comfort.

- It helps protect equipment, stabilise product conditions, and maintain compliance across critical environments.

- Common applications include manufacturing, food processing, pharmaceuticals, data centres, and substations.

- These systems rely on chillers, cooling towers, and heat exchangers to manage heat consistently and efficiently.

- Modern process cooling systems support sustainability goals with smart controls and energy-efficient design.

- Choosing the right setup ensures uptime, lowers energy costs, and scales with your facility’s future needs.

Process Cooling vs Comfort Cooling

One of the most common misconceptions is that process cooling and comfort cooling are interchangeable. While both involve temperature control, they serve very different functions, and understanding the distinction is key for facility and operations managers.

- Comfort Cooling: Designed to keep people comfortable in offices, retail spaces, and hospitality venues.

- Process Cooling: Engineered to maintain specific temperatures in machinery, products, or operational environments.

Comfort cooling is used to create pleasant indoor conditions for occupants. In contrast, process cooling focuses on environmental control for systems and products where temperature stability directly impacts safety, output quality or compliance.

For example, air conditioning in an office is comfort cooling. But cooling a chocolate production line or a pharmaceutical clean room is process cooling, precise, consistent, and vital to how the business operates.

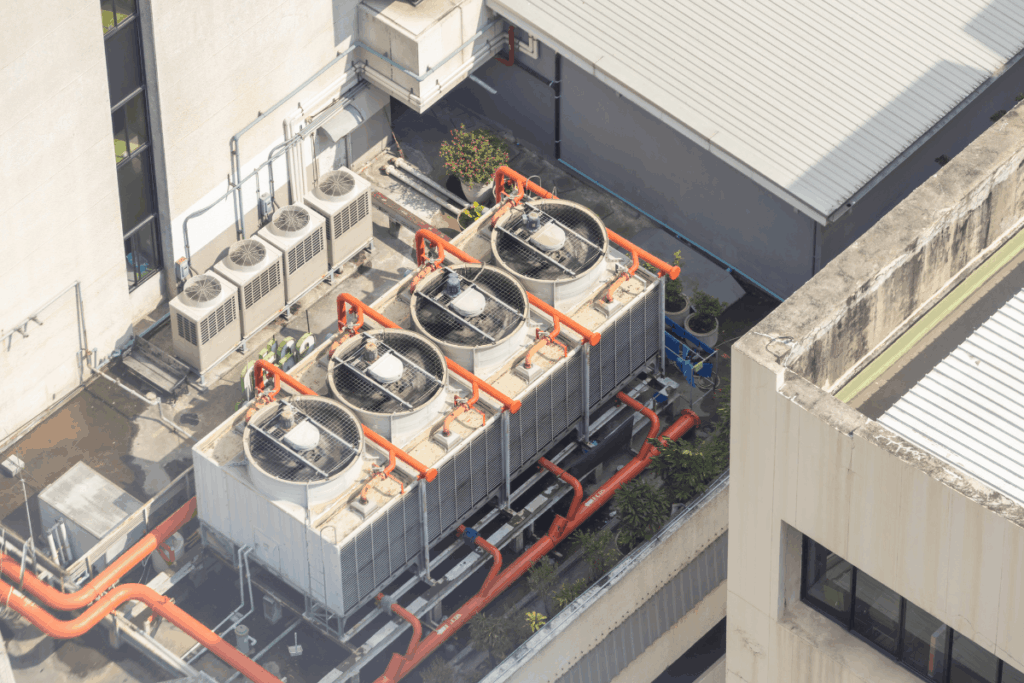

How Process Cooling Works

Process cooling systems are built around the principles of heat transfer. The goal is simple: to capture unwanted heat from a process and discharge it in a controlled, energy-efficient way.

The Process:

- Heat Capture: Heat generated during operation is absorbed by a coolant medium, such as water, refrigerant, or air.

- Heat Transfer: The heated medium is circulated to a system component, such as a chiller, cooling tower, or heat exchanger, that draws out the heat.

- Heat Rejection: The extracted heat is either expelled into the atmosphere or redirected for reuse elsewhere in the facility.

Depending on the application, a process cooling system may include:

- Industrial chillers

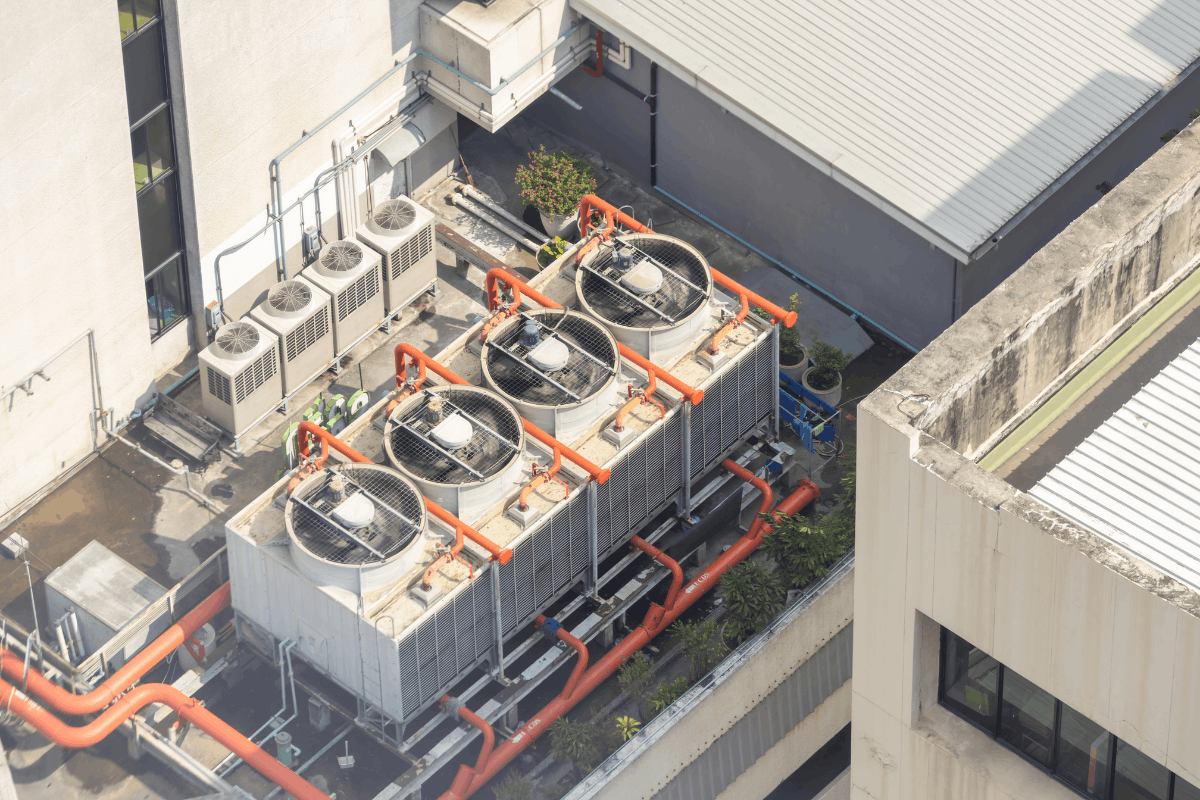

- Cooling towers

- Closed-loop or open-loop circulation systems

- Heat exchangers

Each solution is tailored to suit the facility’s operational requirements, physical layout, and environmental considerations.

Where Process Cooling is Used

Process cooling supports critical operations across a wide range of commercial and industrial environments. While each sector has unique cooling requirements, all depend on consistent temperature control to protect equipment, maintain output quality, and meet compliance obligations.

Manufacturing

High-performance manufacturing environments generate significant heat through continuous machinery use and high-speed production lines. Cooling systems help stabilise conditions and prevent process disruptions caused by overheating.

Common applications include:

- Plastic moulding and extrusion

- CNC machining and metal fabrication

- Paint curing and coating lines

Maintaining consistent temperatures in these settings is essential to avoid warped products, degraded finishes, and equipment stress.

Food & Beverage

Temperature control plays a central role in food and beverage operations, supporting both quality and compliance. Cooling systems are used throughout the production line to manage perishability, ensure hygiene standards are met, and maintain safe storage conditions.

Process cooling is typically required in:

- Cold storage facilities

- Bottling and beverage processing

- Meat, dairy, and ready-to-eat food preparation

These systems also help reduce waste and support shelf life, especially in environments operating under strict food safety guidelines.

Pharmaceuticals & Laboratories

Precision and stability are critical in pharmaceutical production and research environments. Cooling systems ensure environmental conditions remain within narrow tolerances, safeguarding both processes and products.

Applications include:

- Cleanroom climate control

- Active ingredient and compound storage

- Laboratory equipment and testing areas

Effective process cooling helps maintain batch consistency, chemical stability, and regulatory compliance.

Data Centres

With thousands of components running simultaneously, data centres require continuous cooling to prevent thermal spikes that can lead to outages or hardware failure.

Key cooling targets include:

- Server racks and power distribution units

- UPS and networking infrastructure

- Control and monitoring rooms

Reliable cooling protects uptime and ensures systems operate efficiently without energy-intensive overcorrection.

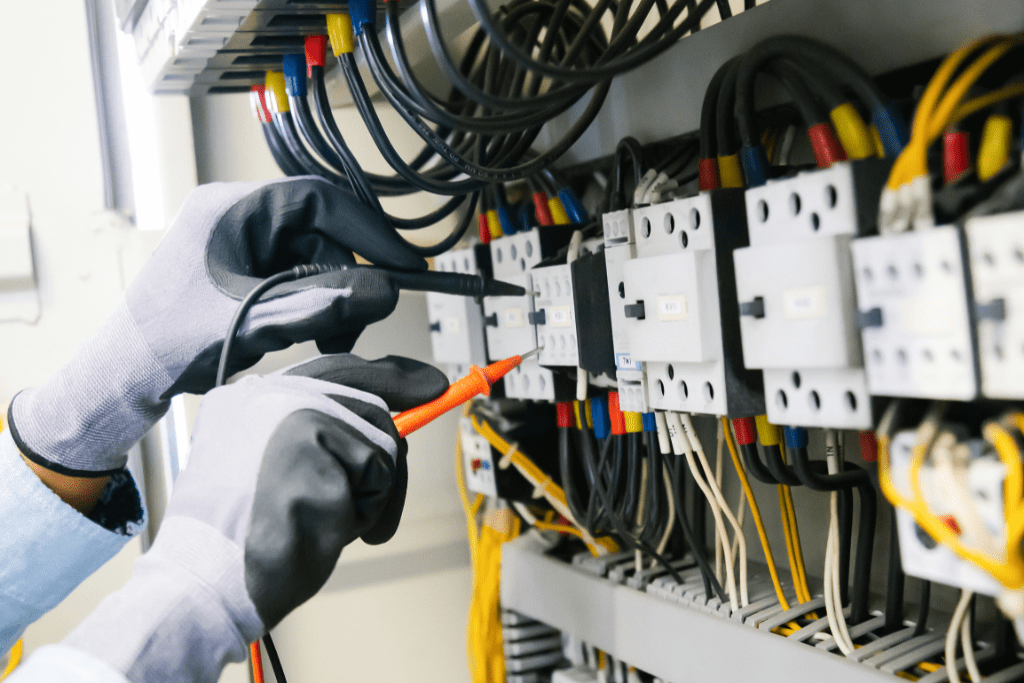

Substations & Control Rooms

Electrical infrastructure naturally generates heat, which can pose serious risks if left unmanaged. Cooling systems are used to maintain safe operating temperatures and extend asset life.

These systems are often installed in:

- Electrical substations and switchrooms

- HV control centres

- Industrial automation panels

Cooling helps mitigate fire risk, reduces unplanned maintenance, and supports uninterrupted operations in critical systems.

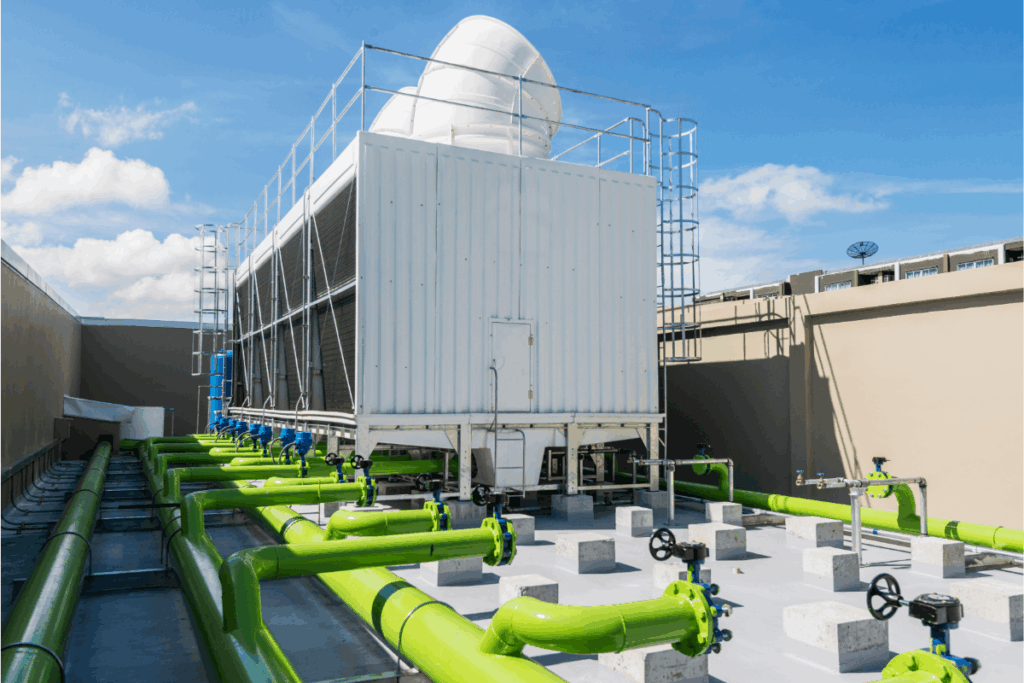

Energy Efficiency and Sustainability Benefits

Answering what is process cooling means looking at the bigger picture, recognising its role beyond operational performance. Beyond temperature control, these systems also support broader goals around energy efficiency and environmental performance in commercial and industrial settings.

Today’s process cooling systems are designed to adapt to demand, reduce waste, and operate with greater control. With the right design, process cooling can lower energy use, extend equipment life, and reduce environmental impact, all without compromising reliability.

Many high-efficiency systems now include:

- Smart controls that adjust cooling output in real time

- Variable-speed drives that minimise energy draw under lighter loads

- Low-GWP refrigerants to help reduce emissions and support compliance

- Closed-loop designs that conserve water and simplify ongoing maintenance

For businesses aiming to improve NABERS or Green Star ratings, or working toward net-zero targets, an efficient process cooling setup delivers measurable benefits both environmentally and financially.

Choosing the Right Cooling System

Once you understand what process cooling is, the next step is selecting a system that aligns with your facility’s specific needs. Every operation is different; what works for a bottling line may not be suitable for a server room or a pharmaceutical lab.

Effective system design starts with a few key factors:

- How much heat your process generates, and how consistently

- The type of equipment or environment that requires cooling

- Physical space, airflow dynamics, and exposure to external conditions

- Potential for operational growth or increased load in the future

- Industry regulations or compliance standards that must be met

Beyond temperature control, a well-designed cooling system contributes to operational efficiency, energy savings, and ongoing compliance. Partnering with specialists who understand the nuances of commercial and industrial environments can make all the difference between a quick fix and a long-term solution.

Keep Your Systems Stable with Purpose-Built Cooling

So, what is process cooling? At its core, it’s about managing heat in a way that protects equipment, stabilises operations, and supports compliance, especially in environments where precision matters.

A well-designed process cooling system doesn’t just keep temperatures in check. It helps reduce downtime, improve energy efficiency, and give operations teams the confidence that systems are running as they should.

If you’re assessing options for process cooling in Perth or planning future upgrades, our team is here to help. We’ll walk you through what’s possible, what to prioritise, and how to move forward, clearly and without obligation.

Frequently Asked Questions

Can process cooling systems be integrated with building management systems?

Yes. Many modern process cooling systems can be integrated with BMS platforms for centralised control, monitoring, and energy optimisation. This integration allows facilities to track system performance, identify issues early, and adjust cooling output based on operational demand, all from a single interface.

How often should process cooling systems be inspected or maintained?

Regular maintenance is essential to keep systems running efficiently and avoid unplanned downtime. Most commercial setups benefit from quarterly inspections, with more critical or high-load systems requiring monthly checks. Maintenance typically includes filter changes, coil cleaning, refrigerant level checks, and calibration of controls.

How do I know if my process requires open-loop or closed-loop cooling?

The choice depends on your process, environment, and water quality needs. Open-loop systems draw water from an external source (like a cooling tower), which may require treatment. Closed-loop systems recirculate fluid within a sealed circuit, offering cleaner operation and reduced water usage. Closed-loop is preferred for sensitive equipment or environments with water restrictions.

Can process cooling systems be used for heat recovery or reuse elsewhere?

Yes. Some advanced systems are designed to capture and repurpose waste heat for other applications, such as space heating, hot water supply, or pre-heating in industrial processes. Integrating heat recovery can significantly improve energy efficiency and contribute to sustainability targets.

Can a process cooling system be scaled as operations grow?

Yes. Many systems can be designed with modularity in mind, allowing additional units or capacity to be added as operational needs increase. Scalability should be discussed during the initial system design phase to ensure expansion can be achieved without major disruption.