A Practical Guide to Understanding Test and Tag

Electrical safety isn’t something most people think about every day, but it plays a crucial role in running a safe and compliant workplace. Whether you’re managing a commercial site, overseeing a business, or working on the tools, it’s essential to keep electrical equipment in good condition and aligned with Australian Standards.

One practical way to do this is through test and tag. If you’re unsure what this involves or how often to schedule it, this guide explains the key steps and requirements.

What is Test and Tag?

Test and tag is a safety process that involves inspecting and electrically testing portable appliances to confirm they are safe to use in the workplace. The process includes two key steps:

- A visual inspection to identify any visible signs of damage or wear

- Electrical testing using a device known as a Portable Appliance Tester (PAT)

If the item passes both checks, a tag is attached showing the test date, the due date for the next test, the result, and the details of the person or company who carried it out.

Technicians follow AS/NZS 3760, the Australian Standard for in-service safety inspection and testing of electrical equipment, when carrying out test and tag procedures.

Why Test and Tag Matters to Your Business

Test and tag supports a safer and more compliant work environment. When done regularly, it helps businesses:

Prevent Electrical Hazards

Damaged or faulty equipment is one of the leading causes of workplace fires and electrical injuries. Routine testing can identify risks early and help prevent serious incidents.

Meet WHS Requirements

Workplace Health and Safety regulations require employers to provide a safe working environment. By testing their commercial electrical equipment regularly, businesses uphold their safety obligations, particularly in industries with high-use or high-wear conditions.

Minimise Equipment Downtime

Identifying issues before they lead to failure helps avoid disruptions to operations and keeps projects on track.

Manage Risk and Liability

In the event of an incident, having a clear test history and up-to-date tagging records can support insurance claims and demonstrate due diligence.

Strengthen Electrical Maintenance Planning

Test and tag fits well within a broader, more regular electrical maintenance service strategy. When used alongside other preventative servicing, it helps improve equipment reliability and reduce long-term costs.

Who Needs to Test and Tag?

If your workplace uses portable appliances that plug into a standard power outlet, there is a good chance that test and tag applies to you. Common examples include:

- Power tools on construction sites

- Kitchen appliances in commercial hospitality settings

- Extension leads and monitors in office spaces

- Workshop machinery and warehouse equipment

- Devices used in education or training facilities

Even low-use items can develop faults over time. For shared or mobile equipment, regular inspection is particularly important to ensure it remains safe and compliant.

How Often Should It Be Done?

How often equipment needs testing depends on where and how the business uses it. Environments with higher risks or harsher conditions typically require more frequent testing.

Environment | Recommended Interval |

Construction or demolition sites | Every 3 months |

Workshops and factories | Every 6 months |

Office and admin environments | Every 12 months |

Hostile or harsh environments | Monthly to quarterly |

Fixed equipment in low-risk areas | Every 5 months |

Each business needs to assess the conditions its equipment operates in and create a testing schedule that reflects the associated risks.

What’s Involved in the Process

Test and tag may seem simple on the surface, but each step plays a vital role in ensuring your workplace stays safe and compliant. Here’s what a standard service includes:

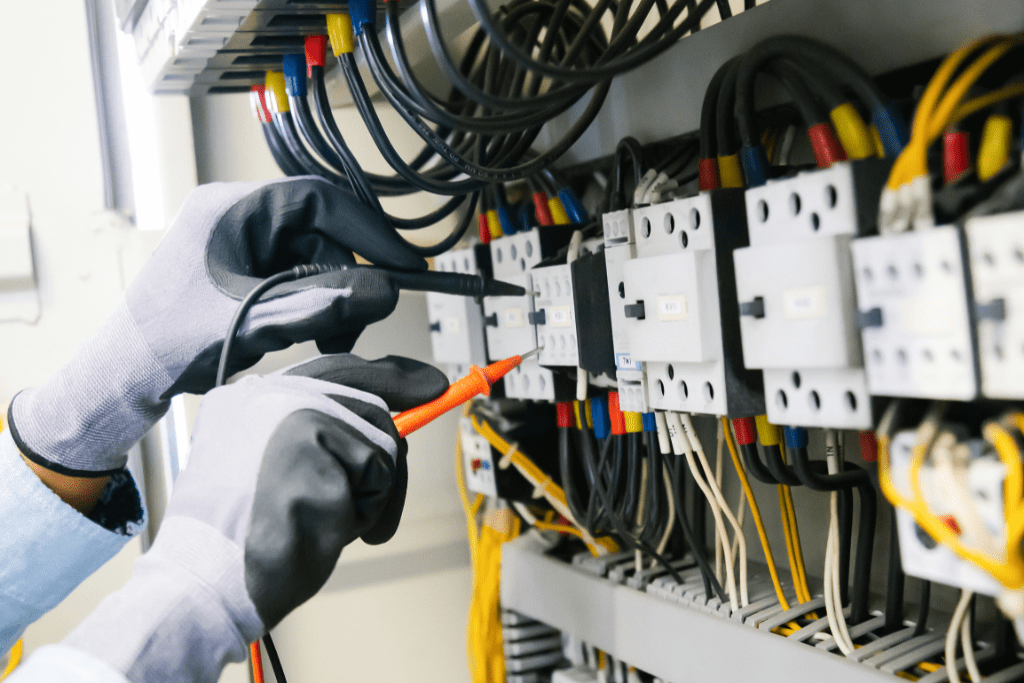

Step 1: Visual Inspection

The technician begins by closely inspecting each appliance for any visible signs of damage or wear. This includes:

- Frayed or exposed wires

- Cracked plugs or loose fittings

- Burn marks or overheating signs

- Missing components or improper repairs

Items with visible damage may be marked as unsafe before testing even begins, helping to eliminate immediate risks on the spot.

Step 2: Electrical Testing

Using a Portable Appliance Tester (PAT), the technician conducts a series of electrical checks to assess the internal safety of the appliance:

- Earth continuity: Confirms the protective earth connection is intact, essential for safely directing fault current.

- Insulation resistance: Checks for potential current leakage that could cause shocks or damage.

- Polarity testing: Ensures that wiring connections are correctly aligned, preventing reverse polarity hazards.

The technician performs these tests in line with AS/NZS 3760 requirements and uses the results to determine whether the appliance passes or fails.

Step 3: Tagging

If the appliance passes all checks, a durable tag is attached. This tag includes:

- The date of the test

- The due date for retesting

- The name or ID of the person or company who performed the test

- A clear pass/fail result

Many businesses use colour-coded tags (often rotated quarterly) to make it easy to identify equipment that’s due for rechecking at a glance.

Step 4: Recordkeeping

While not always legally required, maintaining accurate records of your test and tag results is strongly recommended — especially for businesses in regulated or high-risk sectors. Records may include:

- An asset register of all tested equipment

- Results of each test (including pass/fail status)

- Retest schedules and dates

- Technician credentials

Having these records readily available supports your WHS compliance and simplifies audits, insurance claims, or incident investigations.

Who Can Carry Out Test and Tag?

In Australia, only a competent person — someone with the appropriate training, knowledge, and authorisation — is allowed to carry out test and tag procedures per the national standards.

To meet this standard, the person must:

- Have completed recognised training specific to electrical testing and tagging

- Understand the risks and requirements outlined in AS/NZS 3760

- Be capable of operating a Portable Appliance Tester (PAT) and interpreting its results accurately

- Be authorised to apply compliance tags and maintain relevant records

While it’s not strictly necessary to engage a licensed electrician for basic test and tag, many businesses opt to do so, especially in commercial and high-risk environments. Why?

Because professional commercial electricians bring more than just technical skills. They also offer:

- Peace of mind that testing meets compliance standards

- Consistency and efficiency across large volumes of equipment

- Proper documentation for audits, inspections, or insurance needs

Experienced technicians help maintain high safety and compliance standards by identifying potential issues and making sure every step meets regulatory requirements.

Supporting Safety with Professional Test and Tag Services

When it comes to compliance, workplace safety, and protecting your team, test and tag is one job that’s worth doing right.

At Perth Air & Power Solutions, we work with commercial businesses across Perth to deliver professional test and tag services that meet all legal and industry requirements. Whether you need routine inspections, urgent testing, or a full electrical compliance review, our qualified technicians are here to help.

- Fully certified and experienced

- Same-day service available

- Reliable documentation and tagging

- Integrated electrical, HVAC and refrigeration support if needed

Stay Compliant, Stay Protected

Faulty equipment doesn’t just put your people at risk; it can stop your business in its tracks. With regular test and tag services, you can meet your legal obligations, reduce workplace hazards, and ensure every plug-in appliance is one less thing to worry about.

Need help? Contact Perth Air & Power Solutions today to arrange test and tag for your business, and keep your workplace safe, efficient, and compliant.