How Does Thermal Imaging Work?

When you manage a commercial facility, staying ahead of equipment issues, energy inefficiencies, and safety risks is a constant challenge. A single electrical or HVAC fault can lead to downtime, compliance issues, or rising operational costs.

Thermal imaging offers a smarter, non-invasive way to get ahead of these problems. It identifies heat variations that may signal faults, before they affect performance or safety.

In this guide, we’ll answer the question: how does thermal imaging work? We’ll also explore where it’s most effective in commercial environments, and how it supports more strategic, data-driven maintenance.

Key Takeaways

- Thermal imaging detects heat variations to reveal hidden system faults.

- It’s non-invasive and works on live electrical, HVAC, and refrigeration systems.

- Infrared sensors create thermograms showing temperature differences.

- Accurate results depend on adjusting for emissivity and surface reflections.

- Used in preventative maintenance to avoid downtime and reduce repair costs.

- Supports compliance with detailed, standards-ready reporting.

- Enables smarter, data-driven maintenance and energy efficiency.

How Does Thermal Imaging Work in Practice?

Rather than relying on visual signs or manual inspection, thermal imaging uses highly sensitive sensors to detect small temperature differences across surfaces, giving technicians a real-time view of system health without needing to power anything down.

Here’s what happens inside a commercial-grade thermal imaging camera:

- Infrared Capture: A specialised lens gathers infrared energy emitted by the object or area being inspected.

- Detection: Thousands of microbolometers, uncooled thermal detectors, in the sensor array register subtle temperature changes, often as precise as 0.1°C.

- Signal Conversion: These temperature readings are instantly converted into electrical signals.

- Image Processing: Software translates the data into a thermographic image, applying colour gradients to highlight variations.

- Visual Output: The final image displays abnormal heat patterns that may indicate mechanical stress, failing components, or electrical faults.

Because the process is contactless and safe for live environments, it’s an efficient way to detect issues long before they become operational failures, especially in critical infrastructure where uptime matters.

Understanding the Science of Infrared

Thermal imaging is rooted in physics, specifically the principles of the electromagnetic spectrum. Infrared (IR) radiation sits just beyond visible light and is emitted by all objects warmer than absolute zero. Thermal cameras operate by detecting this specific energy band.

The Role of Heat Transfer in Commercial Faults

Understanding the intricacies of how thermal imaging works is key to interpreting a thermogram correctly. Commercial infrastructure faults are almost always linked to three modes of heat transfer:

- Conduction: Heat transfer through direct physical contact. In electrical systems, a loose terminal or busbar connection creates high resistance, resulting in excessive heat that can conduct into the surrounding components.

- Convection: Heat transfer through the movement of fluids (like air or water). In HVAC, a blockage in a duct or a failing fan motor prevents proper air circulation, causing localised overheating of the motor and inconsistent temperatures in the conditioned space.

- Radiation: Heat transfer via electromagnetic waves (infrared). This is the energy thermal cameras measure. Excessive heat radiated from a component, like an overloaded capacitor or a failing bearing, is the direct visual evidence of a pending fault.

By isolating and measuring heat patterns created by these transfers, thermal imaging provides a quantifiable assessment of system stress that far exceeds what standard visual inspection can offer.

What is Thermal Imaging?

How does thermal imaging work to turn raw data into practical insights? To answer that, it helps to first look at what thermal cameras actually measure. These devices detect infrared emissions from surfaces and convert them into a colour-coded heat map, known as a thermogram.

In commercial settings, this technology gives facility managers and technicians a non-invasive way to assess the condition of systems in real time. Instead of waiting for a fault to trigger alarms or cause downtime, thermal imaging shows exactly where systems are under strain.

By revealing these early warning signs, thermal imaging supports:

- Safer operations by identifying potential fire risks before they escalate

- More efficient energy use by pinpointing insulation gaps and airflow issues

- Longer equipment life through early detection of mechanical wear

- Smarter maintenance decisions, driven by visual evidence, not assumptions

It’s a practical, cost-saving tool that helps businesses stay ahead of faults, reduce operational risk, and optimise performance without interrupting day-to-day operations.

Understanding Emissivity and Reflection

To get accurate readings from a thermal camera, technicians need to account for two key principles: emissivity and reflection. These directly affect how reliable a thermographic image is, especially in commercial settings with mixed materials.

Emissivity

Emissivity refers to how well a material emits infrared radiation. Some materials, like matte paint, rubber, or wood, emit heat efficiently and give accurate readings. Others—particularly shiny metals, like bare switchboard busbars or stainless steel—have low emissivity and can produce misleading results if not adjusted for.

That’s why experienced technicians will:

- Adjust the camera’s emissivity settings based on the surface being scanned

- Use high-emissivity tape or reference targets to get a more reliable temperature reading on reflective surfaces

Reflection

Highly polished or metallic surfaces can also reflect heat from surrounding sources, like the technician or overhead lights. This can create ‘false positives’ that mimic actual hotspots.

Skilled thermographers are trained to:

- Recognise and eliminate reflected heat artefacts

- Use physical positioning and controlled angles to isolate genuine temperature readings

These adjustments are essential for avoiding misdiagnosis and ensuring thermal imaging delivers useful, actionable data, especially in environments like switch rooms, plant areas, and substations.

Thermal Imaging and Preventative Maintenance

Thermal imaging plays an important role in proactive asset management. Highlighting temperature changes in critical systems gives maintenance teams the information needed to make timely, informed decisions, without shutting down operations.

It’s particularly useful for facilities with high-load electrical systems, refrigeration units, or equipment that operates continuously. Regular inspections help identify stress points, inform maintenance schedules, and support overall system reliability.

Detailed Fault Analysis Across Commercial Systems

Understanding the thermal signatures of system stress allows teams to prioritise maintenance and reduce the likelihood of unexpected failures.

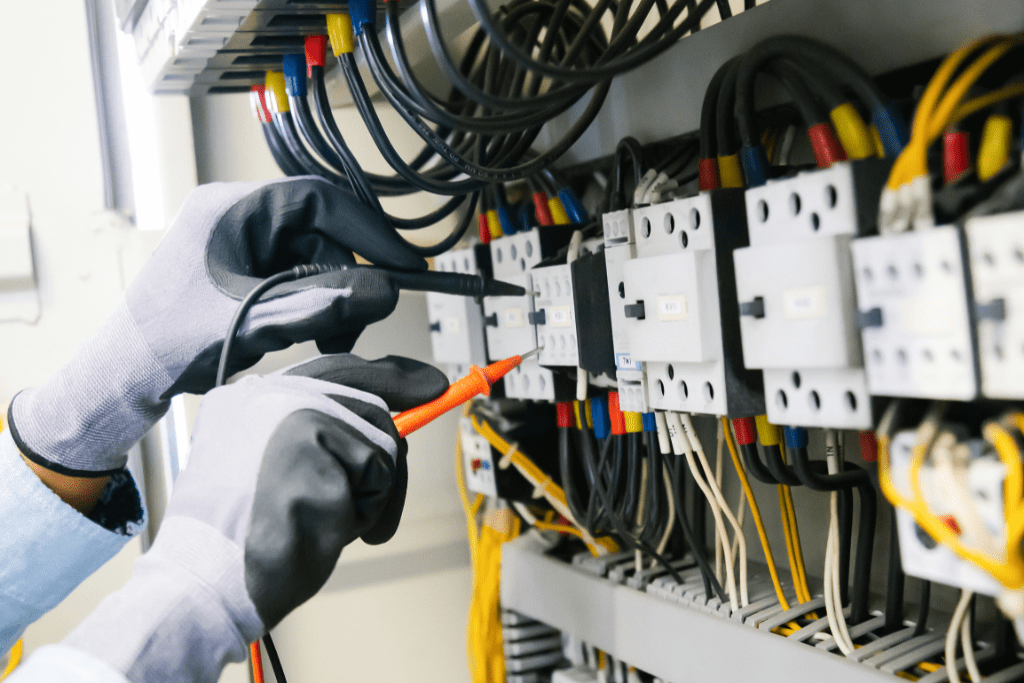

Electrical System Faults

Hotspots in switchboards and control panels usually point to high resistance. Common issues include:

- Loose connections

- Overloaded phases

- Degraded insulation

- Failing fuses or breakers

Even a minor temperature difference (ΔT) of 5°C between components can indicate a fault that needs immediate attention to avoid failure or fire.

HVAC System Faults

Thermal imaging quickly reveals:

- Blocked condenser coils

- Motor and bearing wear in air handling units

- Poor insulation in ductwork

- Uneven cooling across different zones

These issues impact energy use, system performance, and occupant comfort.

Refrigeration and Coolroom Issues

In temperature-sensitive environments, inspections focus on:

- Heat ingress through worn seals or poor insulation

- Thermal bridging in panel joints or structural interfaces

- Overheating in compressor terminals, often linked to high current draw or failing motors

Critical Systems Covered

Experienced technicians also use thermal imaging to inspect the most critical and fault-prone components across your facility’s infrastructure, including:

- Electrical Assets: Main switchboards, distribution boards, transformers, high-load connections, motor control centres (MCCs), and uninterruptible power supplies (UPS).

- HVAC Systems: Identifying airflow obstructions, heat exchanger issues, motor and bearing wear in fans, and verifying effective cooling in server rooms.

- Refrigeration & Coolrooms: Checking compressor terminals, assessing insulation integrity, verifying door seal effectiveness, and detecting potential energy waste or temperature issues.

What It Helps You Achieve:

- Prioritise maintenance based on real performance data, not assumptions.

- Minimise disruption by addressing issues during scheduled downtime.

- Reduce repair costs through earlier intervention and fewer emergency call-outs.

- Increase system longevity with less wear from unnoticed faults.

- Support compliance with thermal reports that meet documentation and audit requirements.

Enhancing Compliance and Audits

Thermal imaging reports provide the documented evidence required for safety audits and insurance purposes. By providing a detailed, time-stamped visual record of system health, you demonstrate proactive risk management and adherence to Australian electrical and safety standards, minimising liability.

For commercial businesses, this translates to more predictable maintenance workflows, improved safety, and better control over operational budgets.

Detailed Reporting and Data Management

The value of a thermal inspection lies not just in the image itself, but in the comprehensive report that supports future asset management and decision-making.

Quantitative vs. Qualitative Reporting

Professional reports include both qualitative and quantitative data:

- Qualitative Inspections: Focus on identifying a visual anomaly, like a hotspot, without precise measurement. This is useful for general fault-finding like spotting leaks or insulation breakdown.

- Quantitative Inspections: Involve precise measurement of temperature differences, often using a Delta T (ΔT). ΔT measures the temperature rise of a component above an acceptable reference point like ambient air, a similar component under the same load, or historical data. This metric is critical for compliance, tracking component deterioration over time, and accurately prioritising repairs based on severity.

A certified thermographer uses this data to classify faults into priority levels (Immediate Attention, Scheduled Repair, Monitor), ensuring maintenance budgets are allocated effectively.

The Thermographic Report Structure

A high-quality report for commercial facilities includes:

- Asset Register Details: Location, equipment type, and serial number.

- Visual Image: A standard photo of the component being inspected.

- Thermal Image: The colour-coded thermogram.

- Temperature Data: Ambient temperature, measured temperature, and the calculated Delta T.

- Clear Recommendations: An explanation of the fault and the required remediation action.

- Compliance Documentation: Confirmation that the survey was performed while the system was under load, adhering to recognised inspection standards.

Safety and Regulatory Framework

For critical commercial infrastructure, thermal imaging is a fundamental element of risk mitigation, directly supporting the safety and regulatory requirements in Australia.

Alignment with Australian Standards

Regular thermal inspection of main switchboards and electrical components helps businesses meet the safety and risk management obligations of the AS/NZS 3000 Wiring Rules.

While the standard does not mandate the technology, it heavily emphasises the need for preventative maintenance to ensure the ongoing integrity of the electrical installation. Thermal data provides objective proof that this preventative maintenance has been performed, protecting both assets and personnel.

Insurance and Risk Management

Many commercial insurance providers require evidence of proactive maintenance, especially for high-risk equipment like main electrical switchboards or heavy-duty industrial refrigeration.

Thermal imaging reports serve as credible documentation for underwriters, potentially reducing liability risk and helping streamline claims processing in the event of a non-thermally related failure. This proactive approach helps businesses avoid costly downtime penalties and demonstrate diligence.

Why Thermal Imaging Matters for Your Operations

Understand the question ‘how does thermal imaging work?’ and it becomes clear how the technology supports safer, smarter, and more cost-effective operations across commercial environments. It provides visual evidence of how systems are operating, making it easier to assess performance without interrupting workflow.

For commercial facilities that rely on electrical, HVAC, or refrigeration infrastructure, these insights support more effective decision-making across day-to-day operations, maintenance planning, and long-term asset management.

Operational Advantages:

- Greater visibility into system health, especially in areas where faults may not be obvious

- Non-intrusive inspections that can be completed while systems remain online

- Better energy efficiency through early identification of heat loss or overloaded equipment

- Improved reporting and accountability, with reliable thermal data to support maintenance logs, audits, and performance reviews

These outcomes are particularly valuable for teams responsible for uptime, safety, and cost control, where accurate insights and early intervention can prevent more serious problems from developing.

Why Partner with Perth Air & Power Solutions?

To turn thermal data into immediate, actionable solutions, you need local expertise that covers all three critical services: electrical, air conditioning, and refrigeration.

At Perth Air & Power Solutions, we combine advanced thermal inspection with comprehensive commercial repair capabilities:

Integrated Service

We provide a complete and comprehensive solution for all your refrigeration, air conditioning and electrical needs, simplifying maintenance planning.

Certified Expertise

Our team consists of dual-certified electrical & refrigerant licensed and qualified technicians, backed by over 15 years of industry experience.

Prompt Response

We offer same-day service options, ensuring we minimise disruption to your business continuity.

Ready to Put Thermal Imaging to Work for Your Business?

Understanding how thermal imaging works is just the beginning. The real advantage comes from working with a team that knows how to apply it accurately, efficiently, and in ways that deliver real operational value.

At Perth Air & Power Solutions, we combine advanced thermal imaging technology with commercial expertise to help you detect issues early, stay compliant, and keep your systems performing at their best.

Get in touch today to schedule a tailored thermal imaging inspection and take the next step toward smarter, safer, and more efficient facility management.