How to Build a Reliable Electrical Maintenance Plan

Electrical systems are one of the most relied-on parts of any commercial building, but they’re also one of the easiest to overlook. Without a clear proactive maintenance plan, issues that start small can lead to system failures, safety risks, and costly downtime. This is where a qualified, dual-certified provider becomes essential.

A structured approach helps your business stay ahead of faults, meet compliance standards, and keep critical equipment operating reliably. In this guide, we break down what to include in your electrical maintenance plan, why preventive maintenance matters, and how to make sure your servicing is working as hard as your systems do.

Key Takeaways

- Create a site-specific maintenance schedule based on risk and usage

- Perform routine inspections to identify wear and early-stage faults

- Test RCDs and emergency lighting in line with AS/NZS standards

- Use thermal imaging and load testing to uncover hidden issues

- Prioritise critical systems with tailored servicing plans

- Maintain clear records to support audits, insurance, and compliance

- Work with a provider experienced in commercial environments

Why Electrical Maintenance Plans Matter

Reliable electrical systems are essential to keeping your operations smooth, safe, and compliant. When faults go undetected or compliance lapses occur, the consequences can include equipment failure, safety incidents, and unexpected downtime.

A proactive approach helps avoid those risks by keeping your systems in check year-round. It also ensures compliance with key Australian Standards like AS/NZS 3760 and AS/NZS 2293 and supports long-term asset management across your facility.

Well-structured electrical maintenance plans offer clear benefits to your business:

- Detect faults early before they cause major issues

- Reduce costly reactive repairs and emergency callouts

- Extend the lifespan of equipment and infrastructure

- Keep documentation up-to-date for audits or certifications

- Ensure safety-critical systems perform when needed most

What to Include in a Commercial Electrical Maintenance Plan

A professional electrical maintenance plan isn’t one-size-fits-all, it should be tailored to your site, equipment load, and compliance requirements. Here’s what a thorough plan should cover:

1. Site Assessment & Custom Schedule

Every industry operates differently. A proper maintenance plan starts with an on-site assessment to review:

- The layout and condition of your electrical infrastructure

- High-use areas or equipment that require closer attention

- Any history of faults, outages, or compliance issues

This assessment helps shape a maintenance schedule that suits your site’s operational demands, balancing compliance with day-to-day needs.

2. Routine Inspections

Regular visual inspections catch early warning signs that could otherwise go unnoticed. These checks typically include:

- Examining outlets, switchboards and wiring for wear or damage

- Identifying signs of overheating, moisture or corrosion

- Flagging overloaded circuits or loose connections

For most sites, inspections are recommended every three to six months, depending on system usage and industry requirements.

3. RCD Testing

Residual Current Devices (RCDs) are one of the most important safety features in any electrical system. They cut power instantly if they detect a fault, reducing the risk of electric shock or fire.

To stay compliant with Australian Standard AS/NZS 3760, RCDs must be tested at scheduled intervals. This includes:

- Trip-time testing: Ensuring the device activates within the required time

- Push-button testing: Verifying the mechanical operation

- Detailed reporting: Keeping records of test dates and outcomes

- Immediate action: Replacing or repairing any failed devices without delay

Failing to test RCDs on time can leave your business exposed to safety risks and compliance penalties, making this a core part of any preventative electrical maintenance plan.

4. Emergency & Exit Lighting Tests

In the event of a power outage, emergency and exit lighting must activate to guide people safely out of the building. These systems are a legal requirement under Australian Standard AS/NZS 2293 and must undergo routine testing.

Your plan should cover:

- Function checks: Ensuring each fitting operates when required

- Battery discharge testing: Confirming lights stay on for at least 90 minutes

- Timely replacement: Swapping out faulty or expired units

Neglecting this can increase liability, especially in workplaces with high foot traffic or multi-exit layouts. Keeping this part of your maintenance process consistent ensures you’re always audit-ready and safety compliant.

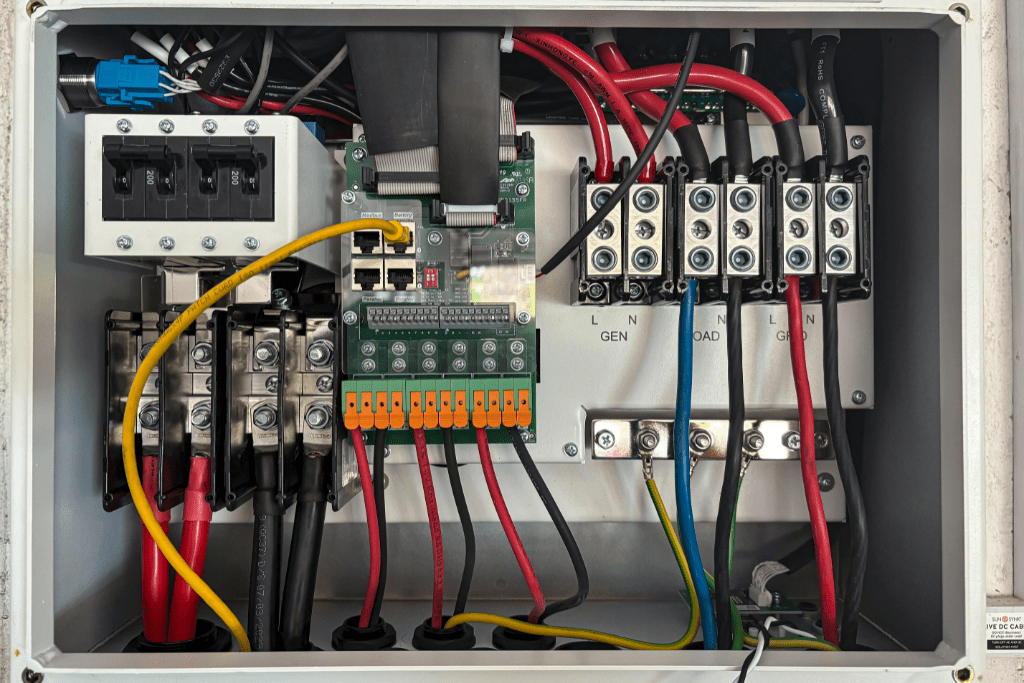

5. Thermal Imaging & Load Testing

Visual inspections can only reveal so much. Thermal imaging and load testing go deeper, identifying hidden faults before they cause major failures.

- Thermal imaging picks up abnormal heat patterns that often indicate loose connections, overloaded circuits, or component wear

- Load testing shows how your system handles real-world demand, revealing imbalances or capacity issues

These diagnostic tools help you act before faults cause downtime or equipment damage. They’re particularly valuable for sites with high electrical loads, older switchboards, or critical operational equipment.

6. Preventive Maintenance for Critical Systems

Certain systems need closer attention due to their importance in daily operations. These may include:

- Server rooms, UPS systems, and IT infrastructure

- Refrigeration units, commercial kitchens, and cool rooms

- Main switchboards or panels that serve essential services

These environments benefit from more frequent checks, part replacements, and function testing. Keeping them in optimal condition is key to avoiding costly downtime and ensuring critical services remain uninterrupted.

7. Compliance Reporting & Documentation

Thorough documentation plays a key role in structured electrical maintenance programs. It ensures that all maintenance activities, inspections, and test results are accurately tracked and available when needed.

A professional provider should supply:

- Up-to-date inspection and testing logs

- Service history reports and asset condition summaries

- Clear recommendations for upgrades, replacements, or safety improvements

These records help demonstrate compliance with industry standards and support internal planning and reporting processes across operations, insurance, and facility management.

Choosing the Right Provider: What to Look For

When selecting a maintenance provider, consistency, responsiveness, and commercial experience matter.

A capable team should be able to:

- Adapt to your specific environment, whether retail, industrial, education, or hospitality

- Provide access to licensed, dual-qualified technicians who understand broader system interactions (HVAC, refrigeration)

- Respond quickly to faults or urgent compliance issues, including same-day support where necessary

- Deliver regular, documented service visits with dependable scheduling

- Communicate clearly, offering updates, explanations, and action plans when needed

A proactive approach and transparent communication help you stay on top of system health without extra admin.

Keep Your Electrical Systems Reliable and Compliant

A structured electrical maintenance plan helps you stay ahead of faults, avoid unnecessary downtime, and meet your compliance obligations, without disrupting daily operations.

Perth Air & Power Solutions delivers tailored, commercial-grade maintenance across Perth. Our dual-certified team handles everything from routine inspections and compliance testing to urgent repairs, with fast response times and a focus on long-term reliability.

Book your site inspection now to get a preventative maintenance plan tailored to your business, or download our checklist to take control of your electrical servicing.

Frequently Asked Questions

What is an electrical maintenance plan?

These plans help businesses manage system performance, reduce unplanned outages, and extend the life of electrical infrastructure. A well-structured maintenance plan includes routine inspections, thermal imaging, RCD testing, emergency lighting checks, and detailed reporting.